Automatic Plastic Side Weld / Bottom Weld / Double Weld Die Cut Bag Making Machine

Basic Info.

| Model NO. | DC-SC-800SBD |

| Speed | High |

| Continuous-Rolled | Yes |

| Sealing & Cutting | Heat-Sealing Heat-Cutting |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | Plastic Bag Making Machine |

| Version | Automatic |

| Total Power | 18.5kw |

| Bag Making Speed | 600PCS/Min |

| Subtype | Biodegradable Bag Making Machine |

| Material | Plastic |

| Machinery | Plastic Package Making Machinery |

| Transport Package | Wooden Case |

| Specification | 8000*1850*1800 mm |

| Trademark | TINUO |

| Origin | Zhejiang |

| HS Code | 8422400090 |

| Production Capacity | 10 Sets Per Month |

Product Description

Product Description

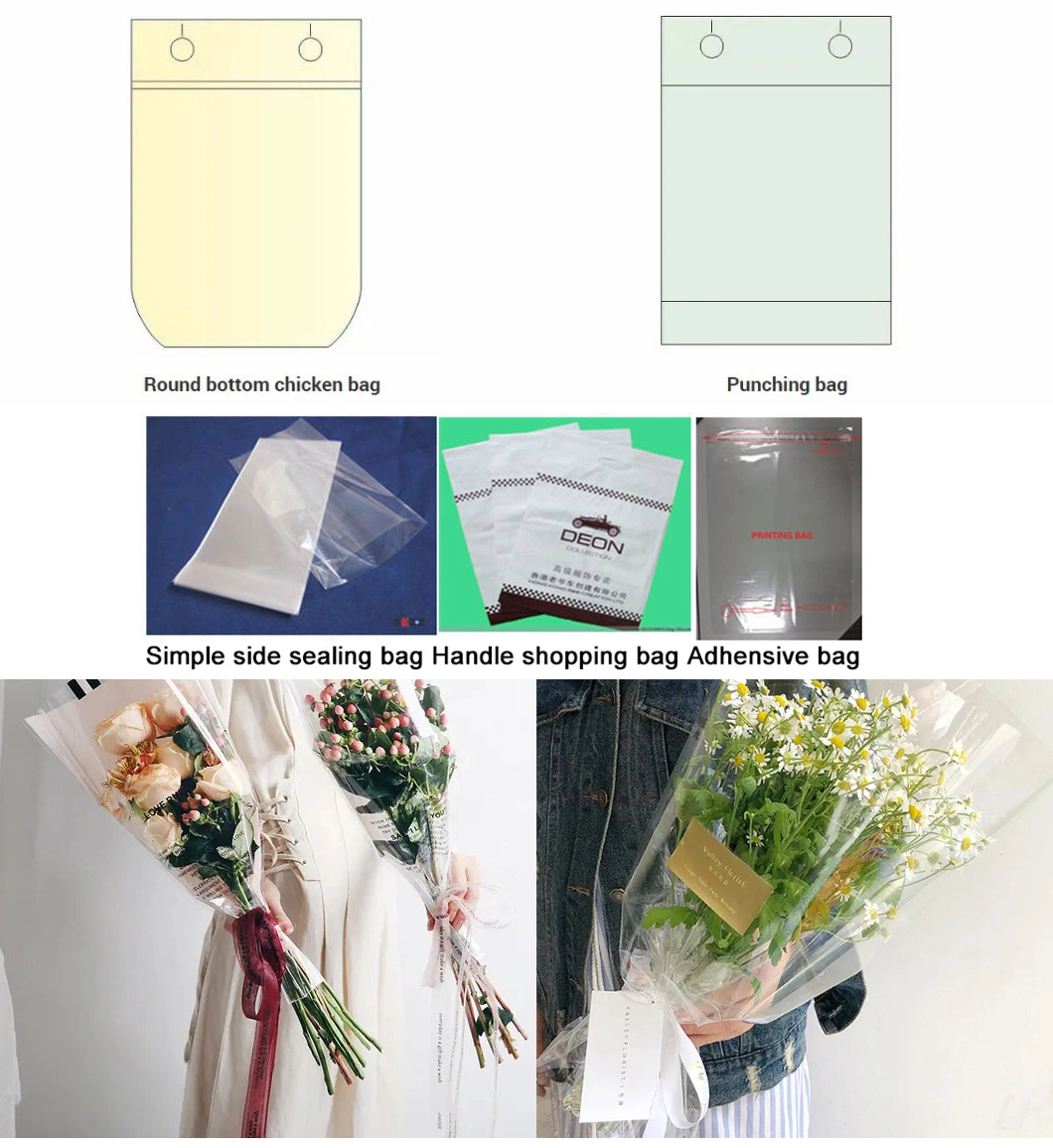

Brief introductionThis machine is multi-function bag making machine. Fully automatic production, easily operation. The machine normal to produce PE material side sealing bag, bottom sealing bag, and double sides sealing bag. The speed of bag according the width size of bag. The max speed of bag making is 200pcs/min. This machine is original design of side sealing bag making machine. so with many different OPTIONAL devices to add to the machine, that the machine can produce many others type bags. Such as handle punch bag, chicken bag, bread bag and OPP header bag etc... Optional devices1 Round bottom chicken bag puncher unit2 OPP header bag device (with pearl film inserted, butterfly punch, adhesive tape and ultrasonic sealing)3 Air hole puncher with rack4 Conveyor table Note: Please be free to send us the required bag samples & bag size to check every details & confirm the bag type in order to work out a proper offer to meet your needs.

Product Parameters

Model | DC-800SBD | DC-800SBD+ZP | ||

Bag type | side seal | double seal | bottom seal | side seal |

Bag height | 750mm | 750mm | 900mm | 750mm |

Bag width | 900mm | 900mm | 750mm | 900mm |

Speed of bag making | ||||

Side seal bag | 180pcs/min | |||

Bottom seal bag | 140pcs/min | |||

Double seal bag | 120pcs/min | |||

OPP bag | 150pcs/min | |||

100pcs/min | ||||

Total power | 8KW | 15KW | ||

Machine weight | 1500kg | 2800kg | ||

| Machine dimension [LxWxH] | 5000 x 1550 x 1870mm | 8000 x 2000 x 2000mm | ||

Air compressor | 5HP | 5HP | ||

Detailed Photos

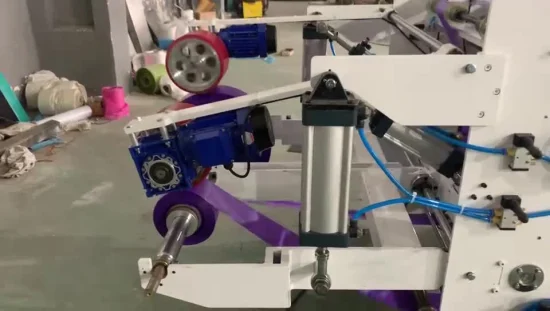

Automatic loading by air cylinder with EPC and tension cont

1 Unwinding adopt automatic loading by air cylidner, max diameter of raw rolling material is φ700mm2 Adopt automatic tension control and EPC system3 Unwinding shaft is heavy-chain plug axle and 1pcs air shaft4 With photocell tracking the edge of film

Triangle folding device (OPTIONAL)

Equipped with Triangle folding device 1600mm (edge folding device,which can fold the big single sheet film into 2 layer smaller folded film)

Top-folding continuously sealing device.+ top fold and handle punch

1 Top-folding continuously sealing, the width size of bag not be limited2 Inside heating wire sealing, which suitfor full colours of bag3 Adopt import heat wire, steady warming, hard sealing4 Double adhesive tape device for side sealing bag5 Top folding device, which can fold the max size from top of bag is 80mm6 Bottom gusset device, which can gusset max size from bottom is 85mm

pre-heating device and photocell for printing tracking

1 Printing image tracking adopts photocell from SICK FROM GERMANY2 The pre-sealing knife is designed specially of bottom four layers film, high speed produce bag 3 Double sides heating, double cylinder driven, strong for gusing, and strong for sealing

Chicken bag device (optional)

1 Two pcs hole punch from top of bag, with 14mm diameter hole 2 pcs 2 With easy break hole punch 3 With EPC and photocell control system4 Broken line device from top of bag, which is easy to tear out

Cutting knife and belt

1 Side sealing knife principal axis transmission belt cylinder lifting and down2 The transmission belt used Habasit from switzerland3 Side sealing knife with water cycle cooling system4 Side sealing knife adopt best of breed material, high temperature heating ametabolic5 Side sealing knife with concealed style heating tube, temperature steady6 Turnover heavy PE side sealing knife, humanism structure design, easy to clean

Company ProfileHot Selling MachinesQ1. How to install and operate the machine?We will show you with English introduction menu and video of machine, or send technician to your factory to train your workers.Q2. What should we charge for your engineer?You should cover engineers' salary, visa cost, air tickets, accommodations, transportation in buyers' country, food, medical care, safety cost, and related cost happens in buyers' country.Q3. How long is your machine's warranty period?All our machine have one year guarantee, starting from finished installation.Q4. How do we solve the machine problem after your engineer leaving?Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time. Engineers will help to take a solution video according your description.